Lightweight, durable, efficient.

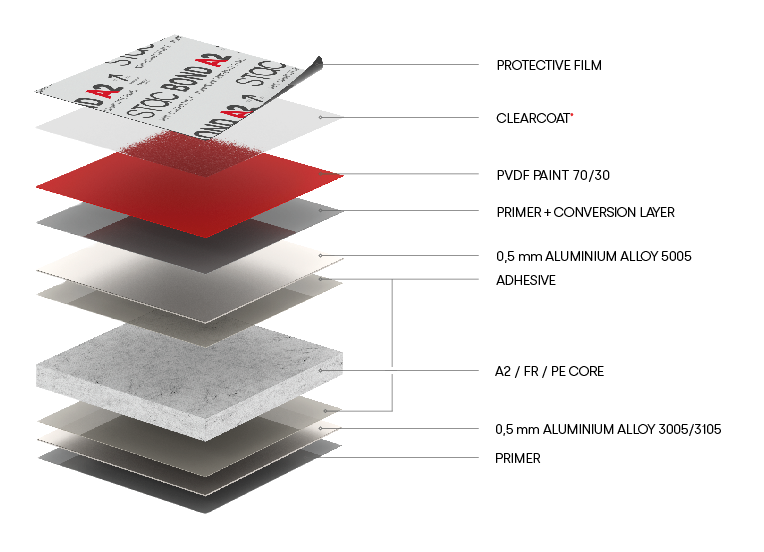

PANEL MAKEUP

A light inner thermoplastic base core, filled with fire-resistant material per request, is sandwiched between layers of protective aluminum alloy, creating a sturdy shell. The outside is then treated with thermoplastic fluoropolymers, highly resistant to solvents, acids and hydrocarbons. Metal composite panels can take any shape and come in any color or texture desired by the customer.

Common traits

- Light as a feather, tough as steel

- Easy to install

- Enduring and stable

- Impact resistant

- Fully recyclable

On the Cutting Edge

We have long been working with proven industry leaders, such as: Alucobond®, Reynobond®, Alpolic®, Vitrabond® and the like. Together we ensure to provide our clients the best result attainable with modern technology.

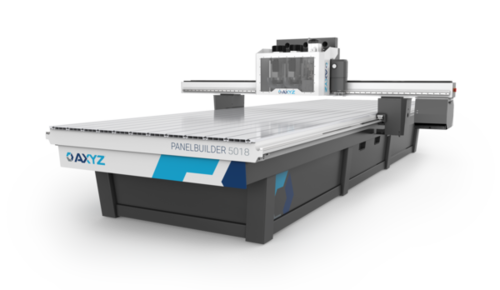

CNC PRECISION

Our composite panel production is powered by Canadian AXYZ™ computer numerical control (CNC) routing solutions. CNC removes the possibility of human error, as opposed to manual, on-site routing, and executes the fabrication process with pin-point accuracy. We use the PANELBuilder 5018, which is designed specifically for processing large volumes of ACM/MCM (aluminum/metal composite material)/HPL (high pressure laminate) and Fiber Cement Board sheets in the fastest and most efficient way possible. The machine can be configured to suit the client’s exact needs. Process areas can be selected from 60″ (1,524mm) x 120″ (3,048mm) to a massive 85″ (2,159mm) x 478″ (12,129mm) or even longer in increments of 24″ (600mm), allowing one or more standard size sheets to be processed at once. Below is a demonstration of the fabrication procedure itself.